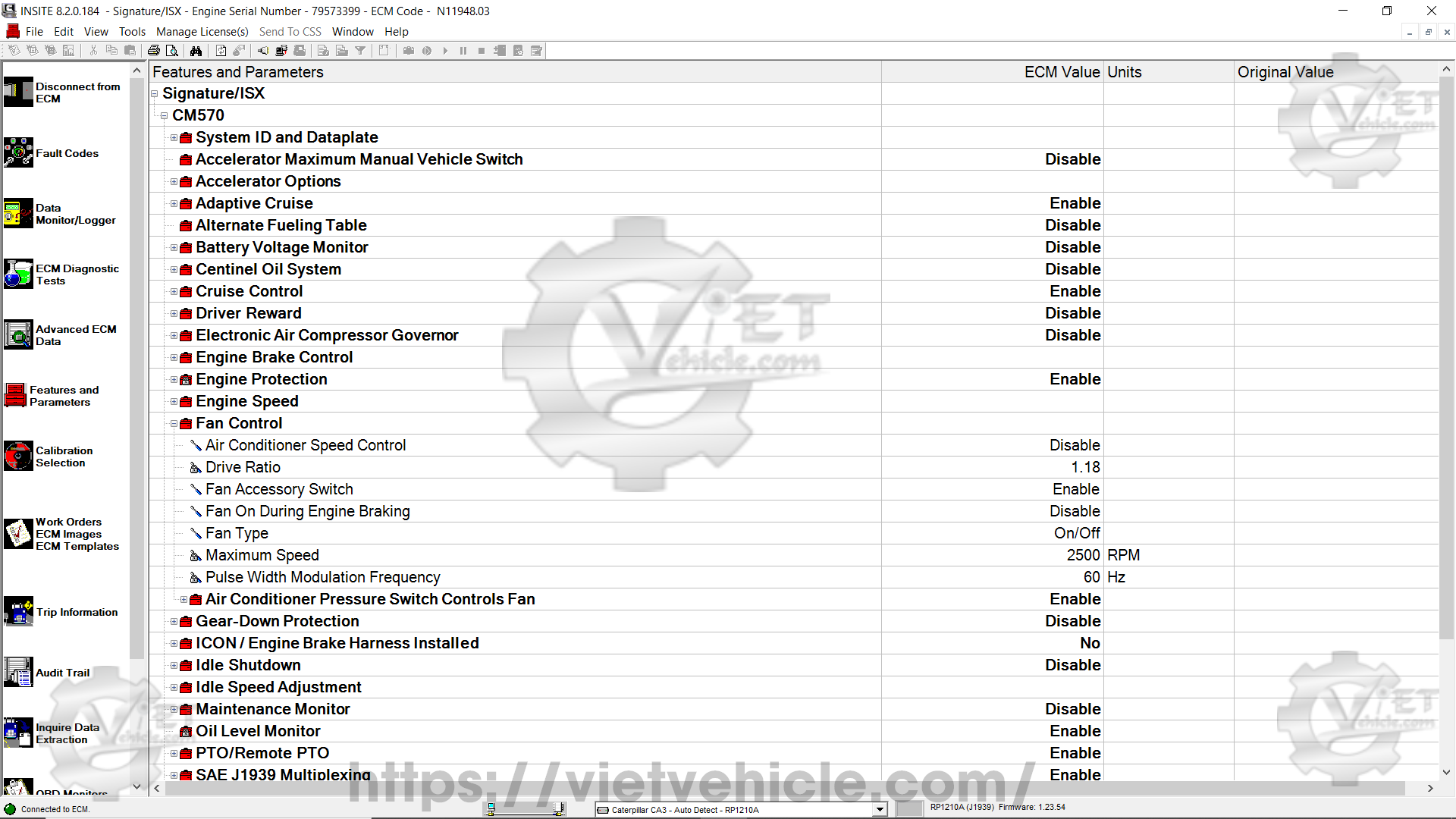

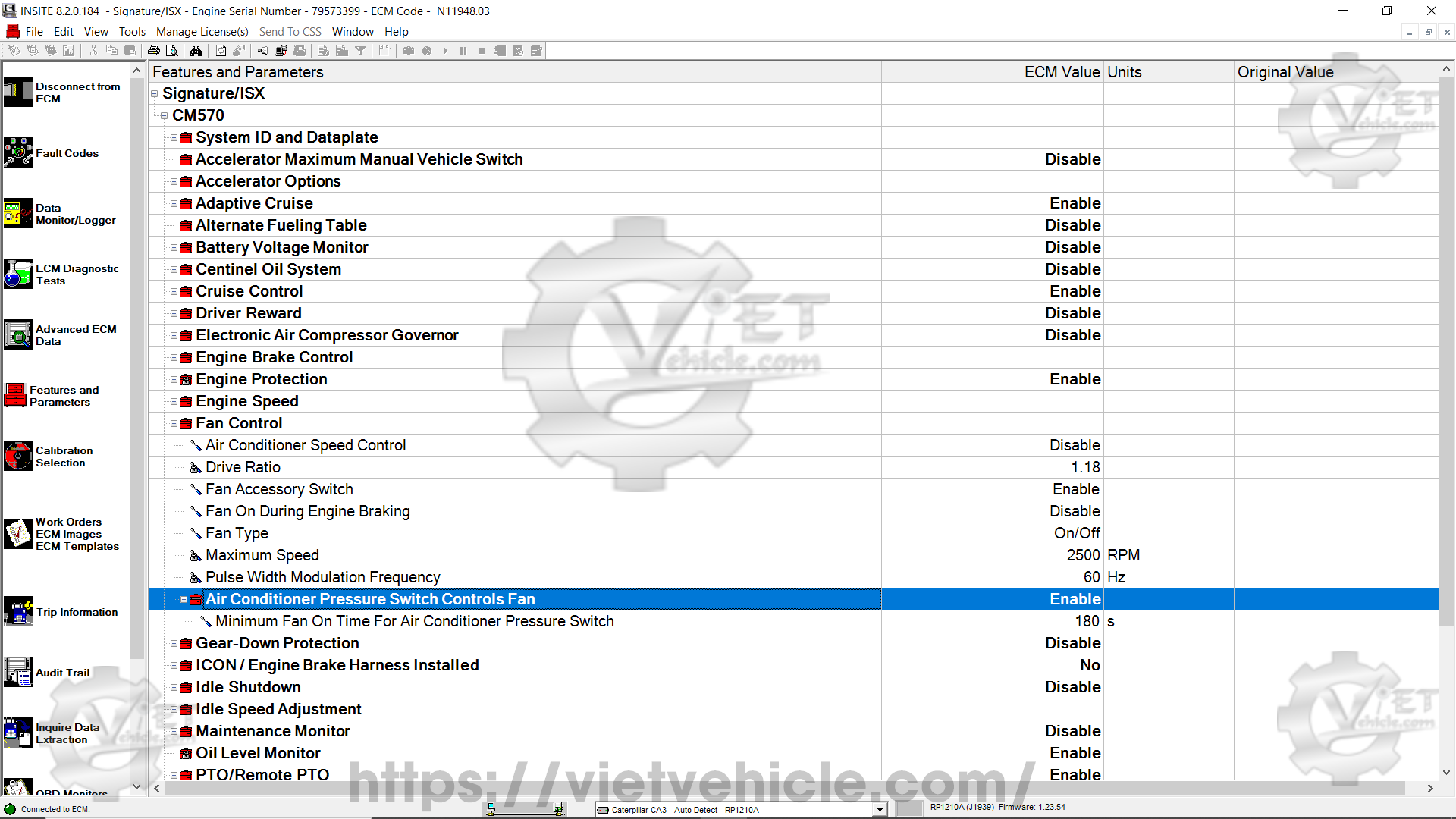

Figure 1.1 – Fan control (features and parameters)

Feature description

The Fan Control feature manages an OEM-supplied fan that supports vehicle and engine systems requiring cooling for proper operation. The ECM controls the fan based on several inputs, including:

Engine operating conditions (coolant temperature, intake manifold temperature, etc.)

Fan overspeed control

Air conditioner operation

Manual fan switch

Engine performance requirements, such as engine braking

Vehicle speed

Adjustable parameters

Fan control

When enabled, this feature allows users to configure fan operation to optimize engine cooling, reduce intake manifold and air conditioner refrigerant temperature, and assist in engine braking.

Fan control logic

This parameter defines the fan voltage logic when Fan Control is enabled:

0 volt on – The fan turns on at 0 volts and off at 12/24 volts.

12/24 volt on – The fan turns on at 12/24 volts and off at 0 volts.

Air conditioner pressure switch input

This enables the ECM to respond to an air conditioner pressure switch installed by the vehicle manufacturer. The ECM will activate the fan based on signals from the pressure switch.

Minimum fan on time for air conditioner pressure switch

This sets the minimum duration the fan runs in response to the air conditioner pressure switch, reducing excessive fan cycling.

Figure 1.2 – Air conditioner pressure switch controls fan

Vehicle speed interaction

When enabled, if the air conditioner turns the fan on while the vehicle is stationary or at low speed, the fan will remain on continuously. The fan will turn off only when the vehicle exceeds a calibrated speed threshold or when the engine is shut down and restarted.

Fan control switch

When enabled, the ECM responds to a manual fan switch installed in the cab by the vehicle manufacturer. This allows the operator to manually turn the fan on, regardless of operating conditions.

Air conditioner speed control

This feature ensures continuous fan operation during idle when the air conditioner is on. If enabled, and the air conditioner pressure switch activates the fan, it remains engaged until the vehicle speed exceeds 6 mph. Once above 6 mph, the fan will continue running for at least the duration set by the minimum fan on time for the air conditioner pressure switch.

Fan on during engine braking

If enabled, the ECM will activate the fan when the engine brakes are applied. This is typically set to occur only during extended braking. For example, some calibrations will turn the fan on if the engine brakes are engaged for more than 15 seconds. This provides additional parasitic load during extended braking.

Heavy-duty engines include a built-in delay that causes the fan to engage only after the engine brakes have been activated.

Fan minimum run time

When enabled, this parameter sets the minimum duration the fan must run when switched on. The minimum run time is determined by calibration settings.

Fan on with remote throttle

When enabled, the ECM will activate the fan when the remote throttle is in use.

Fan type

The ECM controls the fan actuator based on the selected fan type:

On/off – Also known as a “two-speed” fan. Most ECM-controlled fans fall into this category. Many on/off fans use an air-actuated clutch that either fully engages or fully disengages.

Variable speed – Adjusts fan speed as needed to minimize noise and power loss.

Variable speed fan frequency – Defines the required frequency for a variable-speed fan. This value should be provided by the vehicle manufacturer.

Tri-state – Also known as a “three-speed” fan. It operates at a low speed when possible, reducing noise and power loss.

Electronic viscous without speed sensor – Uses an actuator to engage the fan drive when air temperature reaches a specific level. The ECM controls fan speed using a pulse-width modulation (PWM) signal.

Electronic viscous with speed sensor – Similar to the above, but includes a fan speed sensor for precise speed control.

Variable speed without speed sensor – Uses a PWM signal from the ECM to control and adjust speed.

Datalink output – Allows the ECM to accept input from a multiplexed signal.

High-efficiency viscous – Uses a PWM signal to regulate speed at higher frequencies.

Drive ratio

The drive ratio represents the relationship between fan pulley and crankshaft pulley revolutions.

For example, a drive ratio of 1.2 means that for every crankshaft revolution, the fan pulley rotates 1.2 times. The ECM uses this ratio to calculate fan speed and prevent exceeding maximum fan speed. The correct drive ratio must be entered for proper operation (refer to vehicle or fan manufacturer recommendations).

Maximum fan speed

The ECM prevents the fan from exceeding this speed, which is set by the vehicle manufacturer. The correct drive ratio must be entered for this parameter to function correctly.

PWM frequency

Specifies the pulse-width modulation frequency required for a variable-speed fan. This value should be provided by the vehicle manufacturer.

OEM pressure input

When enabled, the OEM pressure sensor controls fan speed.

OEM temperature input

When enabled, the OEM temperature sensor controls fan speed.

Special instructions

The following troubleshooting steps apply:

If the fan does not turn on, verify that the correct fan type is selected.

Most heavy-duty trucks use on/off air-actuated fans.

Many buses and RVs use hydraulically driven fans, which are not ECM-controlled.

Verify system wiring and check whether the fan clutch requires 12 volts or 0 volts to activate.

Confirm whether the ECM fan clutch driver is directly wired to the fan clutch or if a relay is in between.

If the fan stays on continuously, check for a failed air conditioner pressure switch or manual fan switch installed by the OEM.

Ensure that the OEM-installed fan clutch solenoid is properly grounded. If the solenoid grounds through its mounting surface, remove it and clean any paint or corrosion from the contact points.

Disadvantages

Due to heat rejection, the Fan On During Engine Braking feature may behave inconsistently from an operator’s perspective.

For example, if a calibration engages the fan 15 seconds after engine braking starts, the fan may sometimes activate sooner due to factors like:

Air intake temperature

Coolant temperature

Air conditioner pressure switch activation

Contact Us

Whatsapp: +84.858.966.333

Facebook: VIETVehicle Remote Delete Service

YouTube: VIETVehicle – ECM Delete Tuning

Tiktok: VIETVehicle.com

Website: VIETVehicle.com